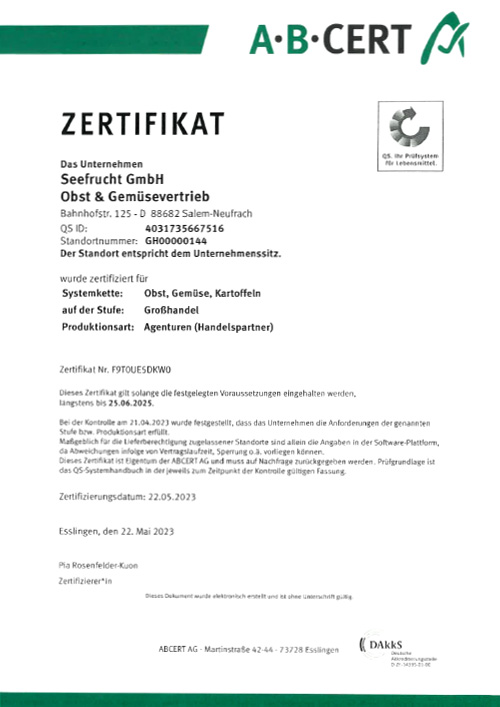

Quality management

Our 180 fruit growers on the northern shore of Lake Constance work according to the guidelines of integrated production and are QS and EurepGap certified.Due to the controlled environmentally friendly cultivation methods, the naturally existing high health value of the products is fully developed.

We also ensure through our QS (Quality Assurance) that all our European producers have and comply with the prescribed certifications. This ensures that the goods can be traced back to each individual producer.

- Supplier loyalty:

All operational processes are traceable for fruit producers, to promote quality-based payment. - Product safety:

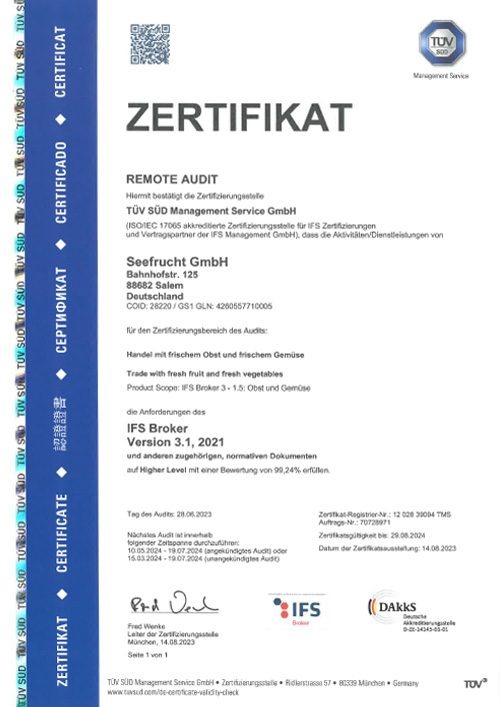

We value and follow the rules of all quality standards such as IP, GlobalGAP, QS, NC and IFS. Because the apple is a sensitive natural product – gentle handling in all phases of marketing is the prerequisite for success with the customer. - Smooth production process:

Through a high standard of technology, continuous modernisation, qualified personnel and comprehensive maintenance of the plants, we avoid errors and downtimes. It is our goal to design and optimise the specific, organisational processes in accordance with IFS and the QS guidelines. - Employee satisfaction:

Committed, motivated employees contribute significantly to the success of the company. For this reason, the management works out short-term and medium-term targets in close cooperation with the responsible employees and evaluates their degree of fulfilment once a year in the quality report (MR). Despite their different backgrounds, our employees can be sure that their concerns are heard, understood and taken into account by the management.

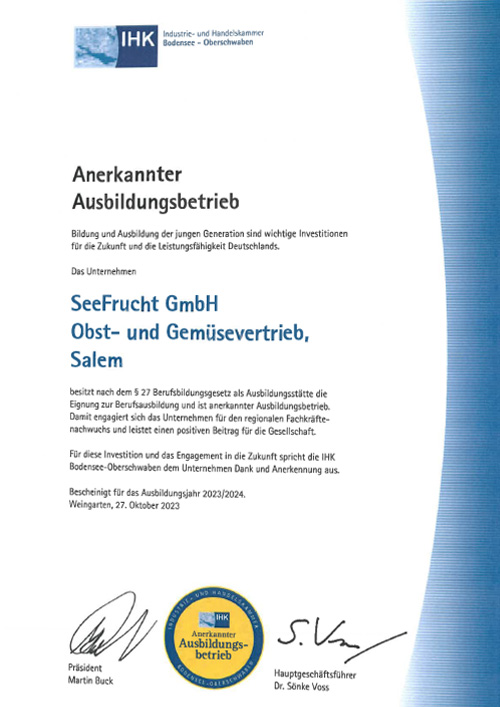

- Training and further education:

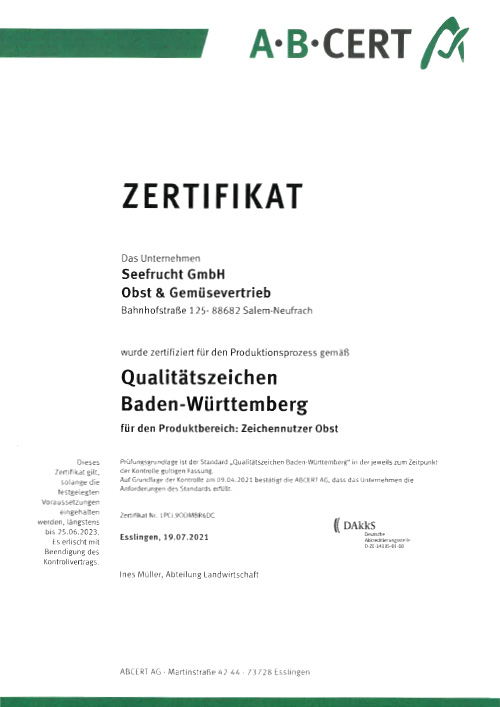

We want to constantly improve. That is why we attach great importance to the regular training of our employees. - Seal of quality:

As a matter of principle, Seefrucht GmbH only accepts apples that at least comply with the IP guidelines or the specifications of the GlobalGAP standard, which excludes the cultivation of GMOs. Through the proper use of quality marks, customers and end consumers can place their trust in our products. It is our goal to design and optimise the specific and organisational processes according to IFS and the QS guidelines. - The residue monitoring is based on the agreements on the use of the quality mark for assured quality from Baden-Württemberg “gQZBW” and those of the quality assurance system QS.

- Protection of the environment:

Our company has a high energy demand in storage and processing. We use the available technical possibilities to protect natural resources and the environment. For us, sustainability means using the best technical possibilities to protect natural resources.